Top Trends in Pharmaceutical Manufacturing for 2025

The pharmaceutical industry is undergoing rapid change in 2025, driven by scientific innovation, digital advances, and global health needs. Pharmaceutical companies are reshaping their operations to improve patient outcomes, strengthen supply chains, and overcome regulatory challenges. From mRNA-based cancer vaccines to anti-aging technologies, the pharma industry is entering a new era of transformation.

Rise of Biosimilars: A New Era

The growing acceptance of biosimilars signals a shift toward cost-effective care. With patents on major biologics expiring, pharmaceutical companies are accelerating production of biosimilars, giving patients access to advanced therapies at lower costs. This movement is expanding treatment options in Health and Healthcare Systems worldwide.

Outsourcing Boom: Strategic Partnerships

Outsourcing is no longer just about saving costs; it has become a core strategic activity. By partnering with specialized manufacturers, pharmaceutical companies can speed up clinical trials, navigate regulatory challenges, and strengthen global supply chains. These alliances help ensure stability and efficiency in an increasingly competitive market.

The Shift to Continuous Manufacturing

Traditional batch processing is giving way to continuous production models. This approach reduces waste, improves quality, and shortens time-to-market for pharmaceutical products. It also supports sustainability by lowering air pollution and optimizing resources across global supply chains.

AI in Quality Assurance: Enhancing Compliance

Artificial intelligence is redefining quality systems across the pharmaceutical industry. From predictive analytics to real-time monitoring, AI ensures compliance with evolving regulations. Automated checks reduce errors, simplify audits, and support strategic activity in complex manufacturing networks.

Digital Transformation: The Role of Automation

Automation is at the heart of digital and technology adoption. Robotics, digital therapeutics, and advanced monitoring tools streamline production while enhancing patient engagement. The shift improves efficiency and helps pharmaceutical companies meet the growing demand for precision therapies.

Green Chemistry: Pioneering Sustainability

As the world addresses climate concerns, pharma industry leaders are adopting green chemistry practices. By reducing toxic byproducts and lowering air pollution, manufacturers are aligning with global environmental goals while ensuring safe drug discovery and production.

Personalized Medicine: Tailoring Treatments

The era of personalized care has arrived. Advances in personalized treatments and genomic research are helping clinicians design therapies that meet individual patient needs. From cell therapy to mRNA-based cancer vaccines, these approaches transform the way care is delivered.

Digital Therapeutics: A New Frontier

Beyond pills and injections, digital therapeutics are creating opportunities for remote monitoring and patient engagement. These tools allow the pharma industry to integrate technology with clinical trials, expanding access and improving outcomes.

Navigating Regulatory Changes: Staying Compliant

Adapting to evolving guidelines is one of the biggest regulatory challenges in 2025. Agencies like the FDA and Medicaid Services require manufacturers to adopt transparent practices and ensure patient safety. Keeping up with global standards is now an essential part of strategic activity.

Nanotechnology in Drug Production: Tiny Innovations

Nanotechnology is unlocking new possibilities in drug discovery. Tiny particles enhance delivery systems, improve absorption, and reduce side effects. This innovation is reshaping how pharmaceutical companies design therapies for complex diseases.

Smart Packaging Solutions: From Production to Delivery

Smart packaging is evolving from simple packaging material to advanced tracking systems. Features like temperature monitoring and digital tags improve patient engagement, ensure product integrity, and strengthen global supply chains.

Cybersecurity in Manufacturing: Protecting Data

With greater reliance on digital systems, the risk of cyber threats grows. Pharmaceutical companies are investing heavily in cybersecurity to safeguard proprietary data, protect clinical trials, and ensure continuity in Health and Healthcare Systems.

Ethics in AI and Biotechnology: Balancing Innovation and Responsibility

As anti-aging technologies, cell therapy, and AI applications expand, ethical considerations are crucial. Manufacturers must balance rapid scientific innovation with responsible practices, ensuring that breakthroughs benefit patients without compromising trust or safety.

About Ritedose

Ritedose is the largest CDMO in the United States specializing in sterile Blow-Fill-Seal (BFS) production of unit dose solutions for the ophthalmic and respiratory markets. Ritedose Pharmaceuticals provides uninterrupted patient access to quality medications every day. With a focus on quality, innovation, and customer satisfaction, the Company partners with leading pharmaceutical companies to deliver safe, effective, and reliable medications that improve patient outcomes. For more information about Ritedose and its services, visit: www.ritedose.com

What Causes Gas And Bloating In Children?

What Causes Gas And Bloating In Children?  The Quiet Factors That Define a Reliable Angiography Device

The Quiet Factors That Define a Reliable Angiography Device  Renting medical equipment can make moving around and being comfortable easier

Renting medical equipment can make moving around and being comfortable easier  Finding the Best ObGyn Near Me: What Every Woman Should Know

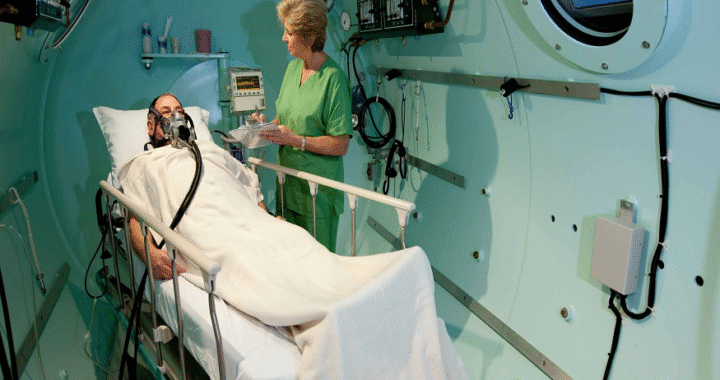

Finding the Best ObGyn Near Me: What Every Woman Should Know  Repairing the Body with Hyperbaric Oxygen Therapy

Repairing the Body with Hyperbaric Oxygen Therapy  Non-Pharmacological Management of COPD: Beyond Medication

Non-Pharmacological Management of COPD: Beyond Medication  Behavior Health / Addiction: Understanding Care, Treatment, and the Path to Recovery

Behavior Health / Addiction: Understanding Care, Treatment, and the Path to Recovery  Lip Fillers in Toronto at BeautyOne Clinic: Enhancing Your Natural Confidence

Lip Fillers in Toronto at BeautyOne Clinic: Enhancing Your Natural Confidence